Mould Accessories

- Home

- /

- Mould Accessories

Mould Accessories

Mould Accessories are essential components that support the efficient and accurate operation of ceramic tile mould systems. Designed for durability and precision, these accessories help improve mould performance, reduce wear, and ensure consistent tile quality during pressing operations.

Electro-Magnetic Upper Plate

The electro-magnetic upper plate uses electric power to hold mould components in position during pressing. While cost-effective and efficient, it requires continuous electricity and can generate heat during operation. Proper care is necessary, as magnetic force may be affected during power outages.

Magnetic Block

Magnetic blocks are positioned at the center of the die box cavities and are used to securely hold lower punches in place during pressing. They utilize magnetic force to ensure accurate positioning and stability throughout the production cycle.

Carbide Liners

Carbide liners are strips with inserts made from extra-hard materials designed to provide high wear resistance. They protect mould components from abrasion and extend the service life of the mould system.

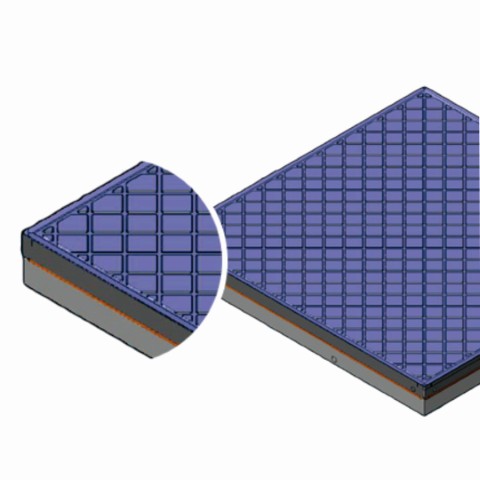

Isostatic Punch (Slot)

Isostatic punch slots can be manufactured as part of the punch body using traditional methods or as metal grids fixed with screws using newer technology. The modern approach offers easier manufacturing and lower compensation costs while maintaining reliable performance.

Leather Bellow

Leather bellows are typically made from natural leather, rubber, or silicone materials. Installed between the base plate and block holder, they provide elasticity to prevent air leakage and maintain stable pressure inside the mould during pressing.

Traditional Punches

Traditional punches feature a simple design with variable depth, typically ranging from 1.6 mm. They are filled with resin of varying thickness, usually starting from 0.6 mm, and are used for standard tile pressing applications.