Ceramic Tile Punch

- Home

- /

- Ceramic Tile Punch

Ceramic Tile Punch

Ceramic Tile Punches are precision components used in tile presses to shape the surface, texture, and structure of ceramic tiles. Designed for accuracy, durability, and wear resistance, these punches play a key role in achieving high-quality tile finishes and consistent production results.

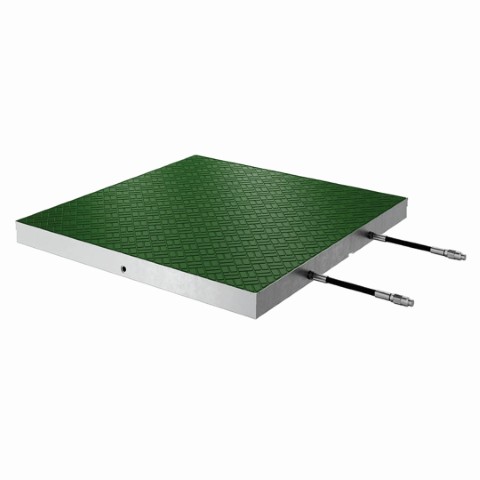

Upper Isostatic Punch

Upper isostatic punches with plugs offer an excellent balance between reliability, pressure compensation, and uniform contact surfaces. This design is especially important during firing, ensuring consistent tile density and improved surface quality.

Plain Punch – Mirror Finish

Plain punches with mirror finish are designed to produce completely or near-completely smooth tile surfaces. They are ideal for applications where a clean, flat, and glossy surface is required on ceramic or porcelain tiles.

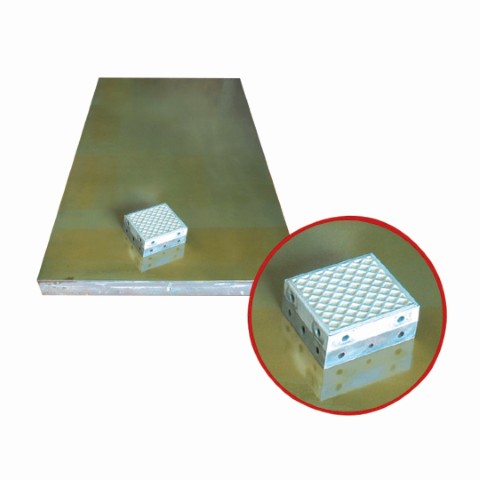

Ceramic Punches

Ceramic punches are chrome-coated to deliver high surface quality and are particularly suitable for pressing unglazed porcelain tiles. The hardening process provides excellent wear resistance, ensuring long service life and stable performance under high-pressure conditions.

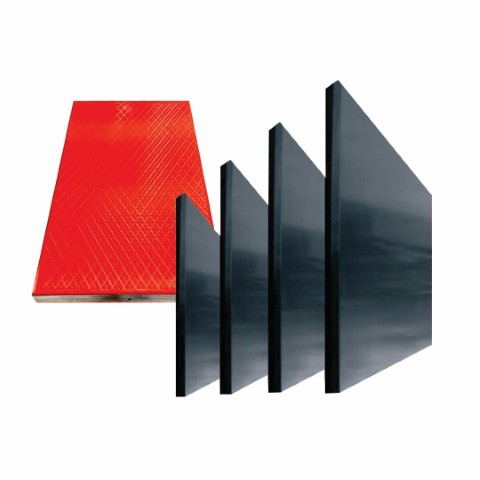

Punches with Edge Spacer

Punches with edge spacers are manufactured from high-strength steel and feature hard-facing on the outer edges. The surface includes rubber or resin layers of varying hardness, allowing customization based on customer requirements. These punches are used to create specific surface effects and controlled textures on tiles.

Elevation Punch

Elevation punches are responsible for shaping both the face and backside of ceramic tiles. They consist of two main parts, including the upper punch, which is installed on the magnetic upper plate, allowing precise texture formation and dimensional control.

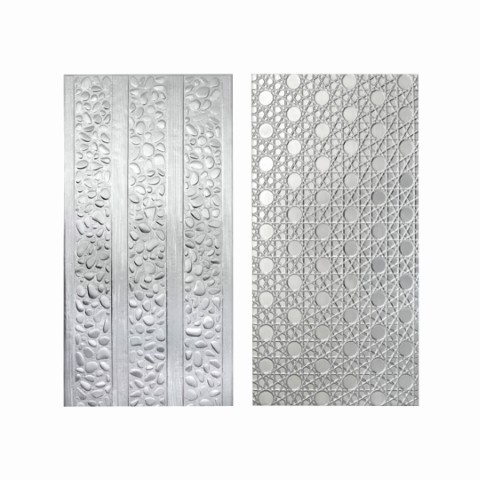

Master Mould

Master moulds are used to create relief textures and decorative patterns on ceramic tiles. They are produced using aluminium and Bakelite punches, enabling consistent replication of designs and high-quality surface detailing.